For Manual Operation HSF (7 Models in Total)

For Manual Operation HSF (7 Models in Total)

The work efficiency of a production line is dramatically improved when using the HSF models. Compared to other models in the HIOS range, a single unit can handle different screw diameters by changing rails. With a screw capacity of 40cc, both models can handle multiple screw diameters. HSF-01 handles 4 screw diameters, and HSF-02 handles 3 screw diameters.

Key Features:

- Low-profile design most suitable for cell production with the width of 55mm.

- It can handle screws with thin heads by adjusting the sensor.

Models Available:

HSF-10 (M1.0)

HSF-12 (M1.2)

HSF-14 (M1.4)

HSF-17 (M1.7)

HSF-20 (M2.0)

HSF-23 (M2.3)

HSF-26 (M2.6)

HSF-30 (M3.0)

Key Information

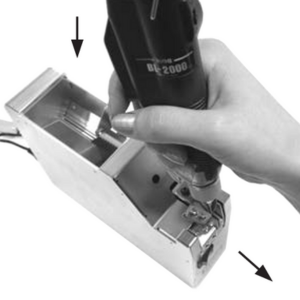

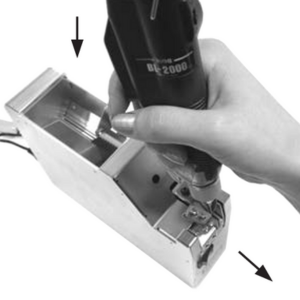

Check operation - If each section has been adjusted properly, screws should be transported to the stopper section, where the electronic screwdriver can take them out. It is worth checking that the screwdriver bit matches the screws being used.

To check for correct operation, place the screwdriver vertically and line up the bit with the cross on the screw head, then move towards you in a horizontal position.

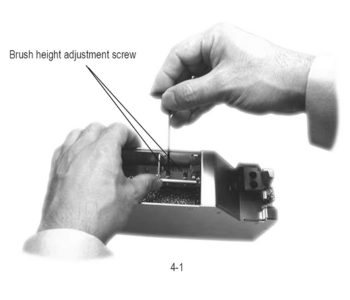

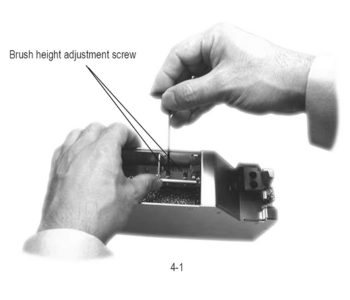

Adjusting the height of the brushes - The brushes in the HSF should rotate at a height where they come in contact with the screw heads going into the rail groove. If adjustement is required, loosen the brush height adjustment screw.