For Manual Operation HSⅢ (8 Models in Total)

For Manual Operation HSⅢ (8 Models in Total)

The work efficiency of a production line will be dramatically improved when using the HSⅢ model. With a screw capacity of 80cc, a single unit can handle different screw diameters by changing rails- 8 screw diameters for the manual operation type, 6 screw diameters for the automatic assembly machines.

Key Features:

- It feeds screws quickly; 120 screws per minute at average / M3 x 8 (for automatic assembly machines).

- Compatible with the suction type (for automatic assembly machines).

Models Available:

HSⅢ-10 (M1.0)

HSⅢ-12 (M1.2)

HSⅢ-14 (M1.4)

HSⅢ-17 (M1.7)

HSⅢ-20 (M2.0)

HSⅢ-23 (M2.3)

HSⅢ-26 (M2.6)

HSⅢ-30 (M3.0)

Key Information

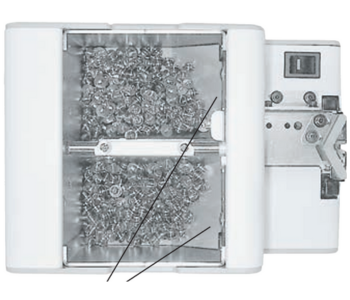

Quantity of screws thrown in - If too many screws are thrown in, orientation and transfer of the screws will be seriously affected. See the diagram on the right for the maximum number of the throw screws in the scooping chamber. Screws should be positioned 2 to 3 mm below the rail groove.

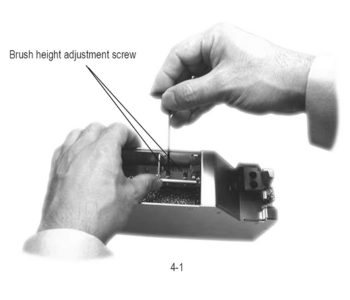

Adjusting the height of the brushes - The brushes in the HSF should rotate at a height where they come in contact with the screw heads going into the rail groove. If adjustement is required, loosen the brush height adjustment screw.