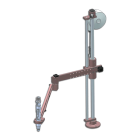

DPC Touch: Sequencing And Process Monitoring Interface

DPC Touch: Sequencing And Process Monitoring Interface

The DPC Touch is an assembly sequence management interface. Compatible with most assembly tools and is the perfect tool for stand-alone workstations.

To ensure quality production, an assembly process needs to be counted, checked, ordered and displayed. All applications can be fulfilled with the DOGA assembly sequence management interface.

Connected to the DOGA torque reaction arms, it will guarantee you optimum quality and traceability.

You can connect the DPC Touch to any DOGA tool (except the BM & BMT series).

Benefits Of The DPC Touch

Ease Of Use

- Simple and user friendly programming

- Process and instructions can be viewed by image or text

- Tolerance settings for every assembly point

Compatibility

- 2 simultaneously coupled tools

- Communication with a PLC

- Cycle called by a bar code reader

- Compatible with screw feeding

Capacity

-255 jobs (or sequences)

- 80 steps per job

- 12 assignable inputs/outputs

- 4 position sensors managed on the positioning arms

Suitable For Use With The Following