The Advantages Of Using A Wireless A Soldering Iron

As technology evolves within electronic manufacturing, soldering irons have continued to adapt to cope with modern day demands. This is never more evident than with JBC.

The recent launch of the B.IRON has led to the successful evolution of a wider range of portable handpieces catering for multiple applications.

Within this article, we will hear directly from our own customers using the B.IRONs in their applications.

Hear directly from the source as to the advantages of using wireless soldering tools below.

A Quick Look At JBC Wireless Soldering Irons

JBC B.IRONs are the next generation of soldering iron, bringing all the power and control of a traditional soldering station into a wireless, battery-powered tool.

Fulfilling the same purpose as JBC's range of soldering stations, the B.IRON range is praised on it's portability aspect alongside its high-end technology.

JBC’s range of tools feature soldering and rework irons that guarantee maximum efficiency.

Below are the current B.IRON tools available:

The Concept Behind The Wireless Soldering Iron

We heard from JBC on how they approached bringing their wireless soldering solutions to the market.

KT - Could you tell us a little bit about where the concept for the B.IRON originated from?

JBC – “In today’s rapidly evolving world, mobility and efficiency are becoming increasingly crucial, particularly in the field of electronic engineering, where multiple projects often run concurrently to achieve optimal solutions."

“Laboratories and R&D departments are frequently faced with the challenge of working on a variety of surface structures, making it essential to have tools that are not only highly efficient but also versatile enough to handle daily tasks."

“B·IRON represents a significant step forward for JBC Soldering Tools, embodying the direction in which our brand is evolving."

KT - So, what does the B.IRON now offer to the consumer who is looking for the next best thing?

JBC - “Our innovative Battery-Powered System offers a new approach to hand soldering and rework processes, allowing operators the freedom to move with ease while maintaining the highest standards of precision and quality, thanks to JBC Technology."

“The B·IRON System is a new product range under the JBC brand, incorporating our Exclusive Heating System, which ensures incredibly fast temperature recovery, reaching 350°C in less than 3 seconds."

“This powerful feature greatly enhances operational efficiency. Additionally, the system includes JBC’s Quick Cartridge Exchanger and an efficient Tip Cleaning System, both designed to boost productivity during hand soldering and rework tasks.”

What Do Our Customers Think?

Our Digital Marketing Executive Ellie, sat down with 2 of our customers, Pickering Interfaces and Impact C.T.S. They spoke about how wireless soldering has improved the way they work, which features of the B·IRON had the biggest impact on their soldering, and more.

Below you will see replies from:

- Steve Baker - Pickering Interfaces

- Robert Bowden - Impact C.T.S

Applications Of The B.IRON

KT – Tell us a bit about your daily soldering applications, and how you might need to use wireless soldering irons.

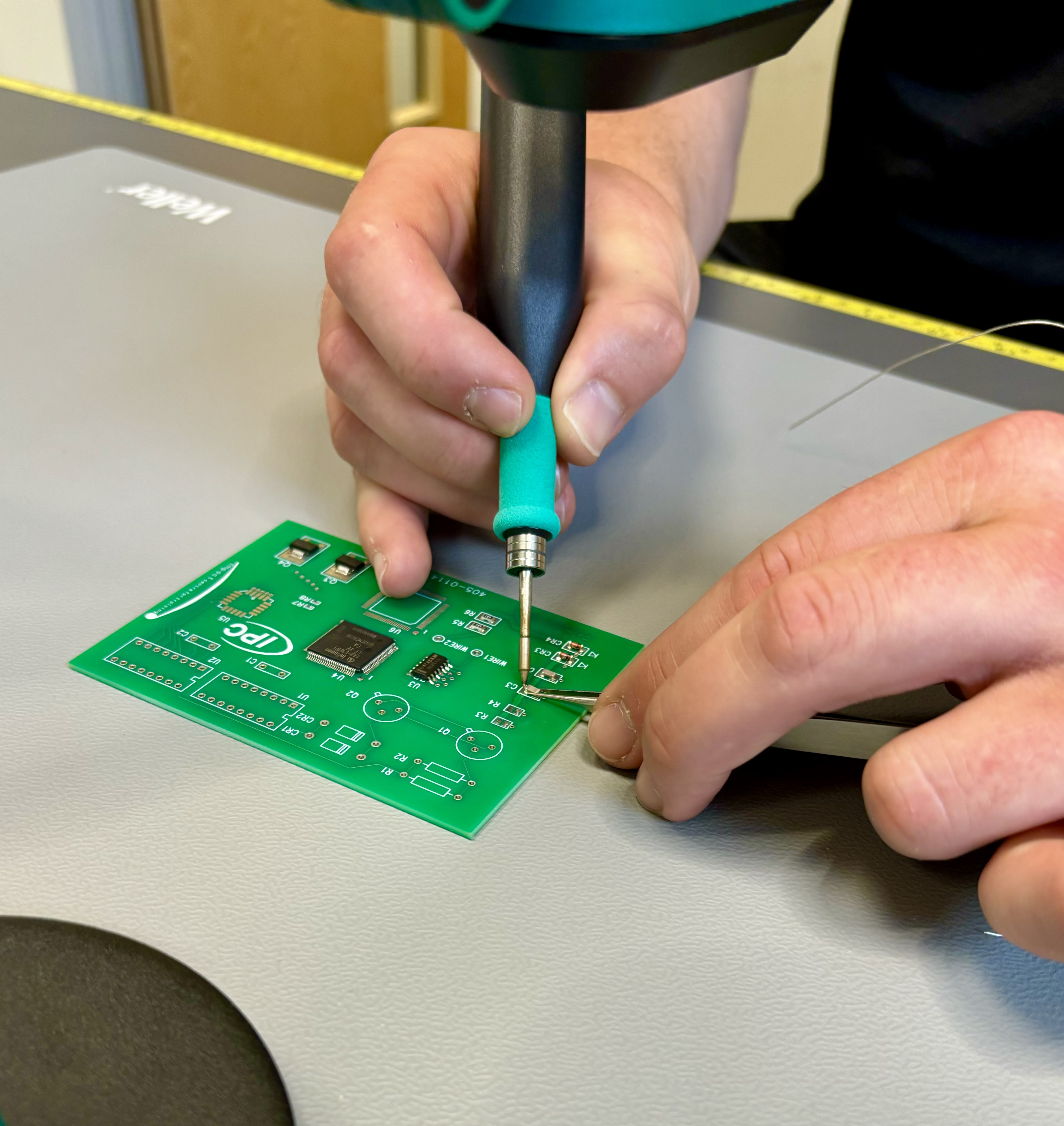

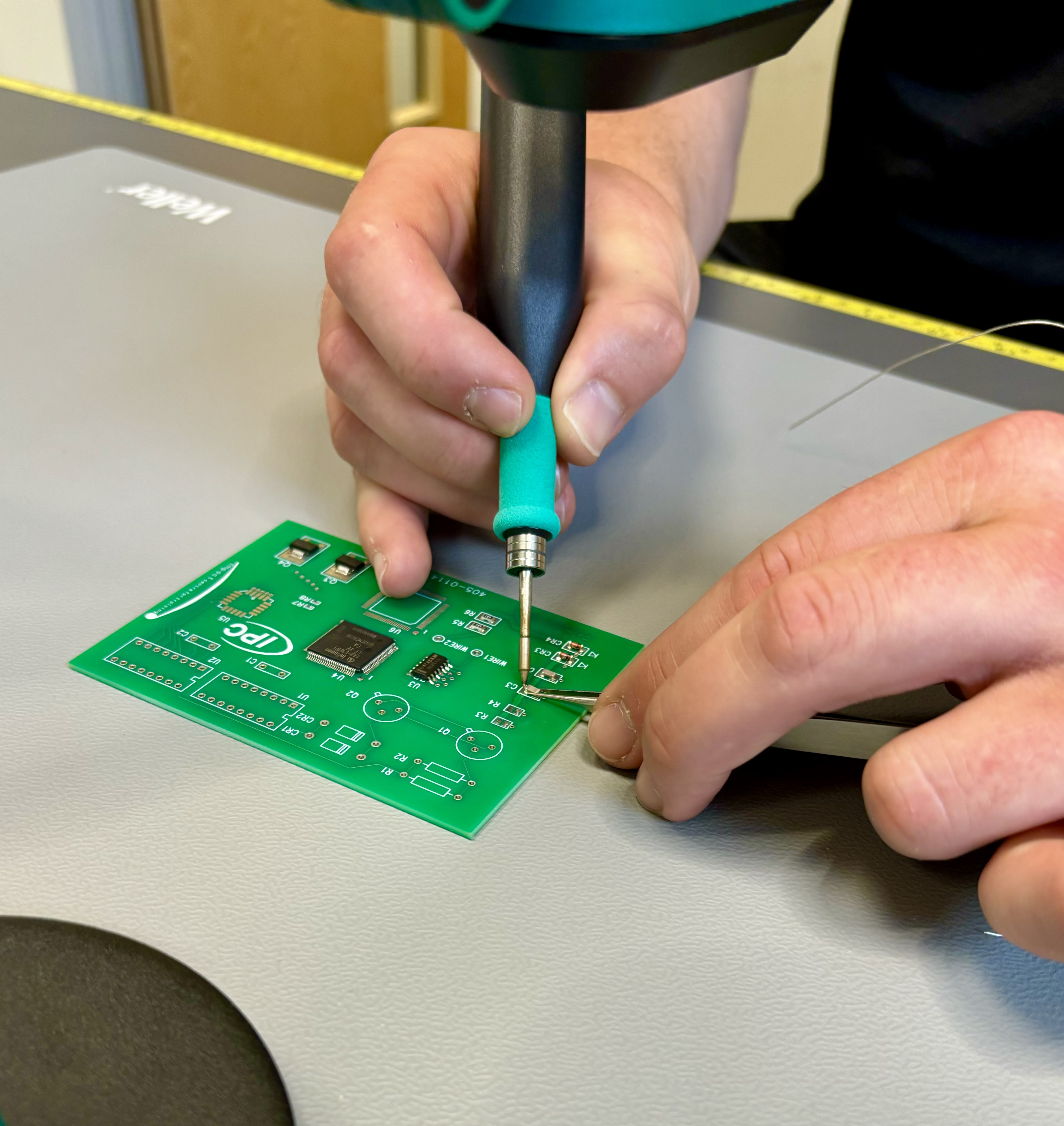

Steve (Pickering Interfaces) - “So, Pickering in the UK, we are a smaller production area than our Czech offices, so we predominantly use JBC soldering stations for rework and repair, mainly surface mount.

“I try to kit the department out with as much JBC equipment as possible, see if the products are productionable and then continue to use.

“We do have an R&D team also where they’re doing little modifications, so in Pickering interface we have actually got quite a few soldering irons in different departments.

“They mostly have similar applications, for example surface mount, through hole, mods, high voltage soldering, stuff like that”

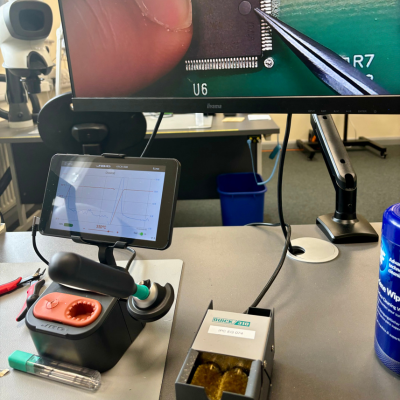

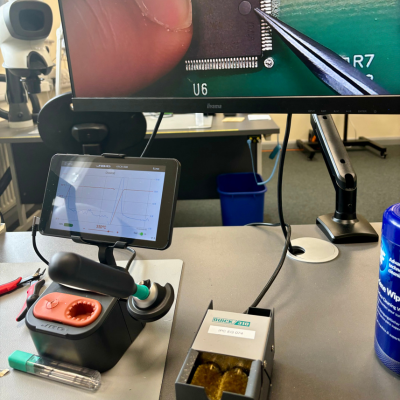

Robert (Impact C.T.S)- "Here at Impact Centre for Training, we roll out IPC courses, organising & delivering high calibre electronic training programs, focusing on global contracts in the military, medical, space and aerospace industry.

“When I sat down and actually thought about what we were going to be using it for, in the training rooms, it made sense for us to have something a little bit more portable.

“We train on a two tier level system, and we train people on a CIS basis. As we are one of the only businesses alongside 3 or 4 companies in the UK who are certified to train people to become trainers themselves, it makes sense for us to have the best equipment.”

KT – What qualities are most important to you from your soldering equipment?

Steve (Pickering Interfaces) - “As our products are niche and high end, we are quite happy to pay more for the quality.

“For us, it’s what suits the product, what gets the best out of the product. With JBC, they give the best results, as they are the most reactive soldering irons, the tip to board contact is quite quick, with a lot of longevity in the tips.

“This is exactly what we need when looking for a soldering station”

Best Features & Advantages Of A Wireless Soldering Iron

KT – How has the B.IRON improved your soldering results?

Steve (Pickering Interfaces) - “In terms of use, the B.IRON works for us as there are times when we need to be soldering away from our rework stations.

“There has even been times when one of our pick and place machines has gone down and we need to solder a joint.

“To unplug all the soldering iron previously was a real pain, so I looked at the B.IRON and it has been perfect to put the cap on, put it in our pocket, and move around the room when we need.

“For the time when the B.IRON is fully charged, it is really reactive, quick change over of the tips and there was no struggle with the tip temperatures.”

Robert (Impact C.T.S) - “The main difference we’ve seen is an improvement with the handpiece, due to an ergonomic issue in the industry.

“For example, the handpieces on the Weller stations are much bigger, so going from that, I think the B.IRON gives more ease of use and comfort for the operator.

“And we’ve tested loads of stations, but we have found that JBC are the best, as far as comfort and positioning of parts on the handpiece are concerned”

KT – What is your favourite feature of the B.IRON?

Robert (Impact C.T.S) - “How portable and how light the B.IRON is!

“I’ve got a number of stations here with burn marks going through leads being attached to the station, people getting tangled up in the wires and things like that.

“So I wanted something light, professional and accurate. It gave me all of those things.

“The cap is fantastic, because in one of the courses we do, solder tip awareness, showcasing the importance of looking after tips is huge. As there is a general lack of education around this topic, the cap brings a great sense of awareness of looking after your soldering tips.”

User Experiences With Wireless Soldering Irons In Training Facilities

KT – From the training courses you have held using the B.IRON, what feedback do the users have?

Robert (Impact C.T.S) – “From a customer’s point of view, I think we’ve done a test trial with about 3 customers, we have had SAB, Defence, Sony to do a J-Standard course, and Redbull, and the feedback has been amazing!

“The thing is, the difference between the nano-stations and the B.IRON is small, as there isn’t much change in terms of what it can do.

“But the portability and the convenience of not having anything attached is fantastic!

“We’ve only given it a few weeks and the feedback has been brilliant. With things like the B.IRON, it’s so accurate, it’s unbelievable. And because of the positioning where you put your fingers being lower down, there is much more accuracy which is great for soldering joints”

In Summary

Hopefully, this case study has shared some insight into how the B.IRON has signifcantly improved the experience of solderers in different environments.

Wireless soldering irons cater for a wide spectrum of requirements, from the convenience of portability, the rapid heat up time and the ease of use due to the ergonomic design.

If you are interested in purchasing or trialing any of the JBC wireless soldering range, get in touch with our team today!